Specialist Houston Welding Inspection: Ensuring Structural Integrity and Safety

Wiki Article

Discovering the Basics of Welding Inspection: An In-depth Evaluation of Processes, Tools, and the Value of Quality Assurance in Welding Industries

Welding evaluation offers as a foundation in the maintenance of security and structural integrity across different industries. Recognizing the implications of these practices increases vital inquiries regarding their efficiency and the future direction of high quality guarantee in welding.Significance of Welding Examination

Welding evaluation plays a vital role in ensuring the integrity and safety of bonded structures. It works as an organized strategy to assessing weld high quality, recognizing prospective problems, and making sure compliance with established requirements and specifications. The relevance of welding assessment expands beyond mere adherence to regulations; it is critical in safeguarding human lives and protecting financial investments in framework.Defective welds can bring about devastating failures, leading to considerable financial losses, injury, or loss of life. Consequently, extensive assessment processes are vital to discover concerns such as insufficient infiltration, porosity, or cracks prior to they intensify into important failings. Additionally, efficient welding assessment adds to the general efficiency and durability of structures, guaranteeing that they can hold up against the problems for which they were created.

Furthermore, the application of welding examination cultivates a society of top quality and responsibility within the welding industry. By focusing on evaluation, companies show their commitment to quality, therefore enhancing their track record and competitiveness in the marketplace. Inevitably, welding evaluation is not merely a step-by-step step however a fundamental part of engineering integrity and security guarantee, vital for the successful implementation of welding jobs throughout various industries.

Trick Inspection Processes

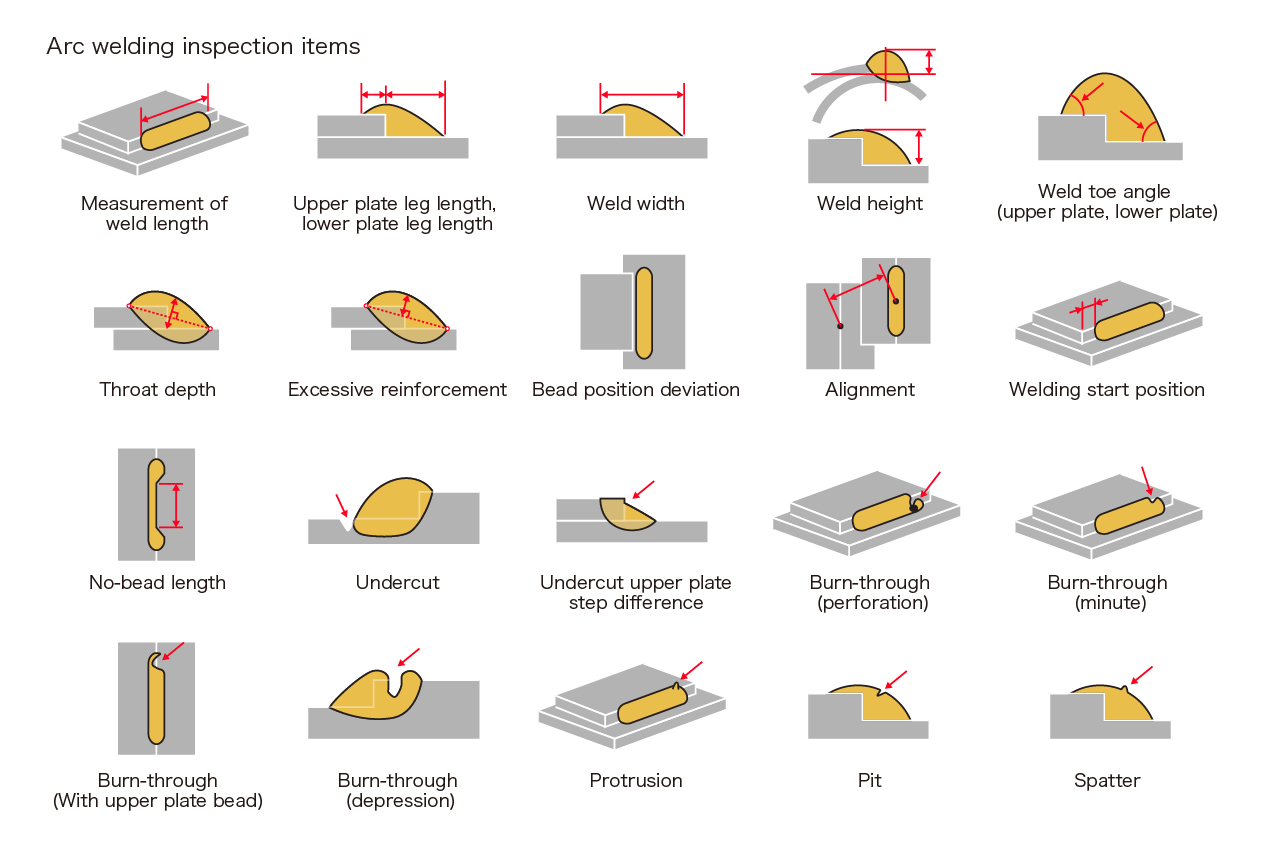

A thorough approach to welding assessment involves several crucial procedures that are important for making sure weld high quality and architectural stability. The initial vital process is visual examination, which allows examiners to determine surface area problems such as fractures, porosity, and improper bead appearance. This technique acts as an initial analysis to make sure that the weld fulfills defined requirements.

Additionally, destructive testing might be executed on example welds to examine their mechanical buildings and efficiency under stress. This process entails effect, fatigue, and tensile screening to verify that the weld can endure functional problems.

Finally, paperwork and reporting are essential parts of the assessment procedure. Preserving accurate documents of assessments, monitorings, and examination results helps make certain compliance with sector criteria and assists in continuous enhancement in welding techniques. Jointly, these essential processes create the backbone of efficient welding assessment and high quality guarantee.

Tools for Weld Analysis

Many tools are necessary for effective weld analysis, each made to examine various aspects of weld top quality and performance. Among one of the most commonly utilized are aesthetic evaluation devices, consisting of magnifying glasses and borescopes, which make it possible for examiners to recognize surface flaws such as cracks, porosity, and incorrect combination.In addition, ultrasonic testing (UT) devices is critical for discovering interior flaws. This device uses high-frequency audio waves to expose discontinuities within the weld, guaranteeing the integrity of the material. Radiographic testing (RT) devices, which use X-rays or gamma rays, in a similar way provide insight right into the internal structure of welds, permitting the recognition of inclusions click to read more or voids.

For exact dimensions, calipers and determines play a significant role in making sure and figuring out weld measurements adherence to defined resistances. Hardness testers assess the mechanical residential or commercial properties of the weld, ensuring it fulfills performance standards.

Strategies for Assessing Quality

How can the quality of welds be reliably analyzed? A selection of methods are utilized to examine weld honesty and ensure adherence to specified criteria. Aesthetic evaluation is the most basic technique, allowing assessors to determine surface area flaws such as cracks, porosity, or damaging. This non-destructive technique works as an initial evaluation before more innovative methods are made use of.Ultrasonic testing (UT) is another famous strategy that utilizes high-frequency acoustic waves to find inner defects within the weld. Houston Welding Inspection. This approach offers a detailed view of the weld's stability investigate this site without endangering its architectural integrity. In enhancement, radiographic testing (RT) utilizes X-rays or gamma rays to reveal internal issues, offering in-depth understandings into weld top quality

Magnetic fragment testing (MT) is efficient for detecting surface area and near-surface suspensions in ferromagnetic materials, using magnetic fields and colored bits to highlight problems. Dye penetrant testing (PT) can be employed to discover surface-breaking imperfections by applying a dye that permeates right into splits and is ultimately revealed.

Compliance With Industry Standards

Compliance with market requirements is vital for making certain the quality and safety of welded structures. These standards, developed by organizations such as the American Welding Culture (AWS) and the American National Standards Institute (ANSI), supply standards that control the welding procedure, materials, and assessment methods. Following these requirements not only guarantees the architectural stability of welds however additionally minimizes threats connected with failings that can result in disastrous repercussions.

Welding inspectors are entrusted with confirming compliance with these standards throughout the welding procedure (Houston Welding Inspection). This entails examining welding procedures, keeping track of welder qualifications, and performing complete evaluations of the final item. Non-compliance can cause considerable financial effects, task delays, and damage to a company's track record

Routine training and updates on standards are crucial to keep employees informed and proficient, making sure that all aspects of welding procedures fulfill or exceed regulative needs. Eventually, dedication to sector standards offers as a foundation for quality in the welding industry, promoting safety and security and reliability in welded structures.

Conclusion

In verdict, welding assessment offers as an essential part in maintaining the safety and security and integrity of bonded structures. Adherence to industry standards ensures conformity and advertises a culture of top quality within the welding sector.In addition, the execution of welding examination promotes a culture of high quality and responsibility within the welding industry. Ultimately, welding inspection is not just a step-by-step step yet an essential component of design stability Learn More and safety and security guarantee, important for the effective execution of welding tasks across various markets.

An extensive approach to welding assessment involves numerous essential processes that are crucial for guaranteeing weld top quality and structural stability. These standards, established by companies such as the American Welding Society (AWS) and the American National Criteria Institute (ANSI), give guidelines that regulate the welding procedure, products, and inspection protocols.Welding assessors are tasked with confirming conformity with these standards throughout the welding procedure.

Report this wiki page